top of page

Features

FEATURES

Magnetic Switch with manual air pulse jet cleaning button

3-Stage Filtration System

Water Releasing Device

Optional HEPA Filter

3-Stage Filtrations

Stage 1. >

Aluminum Mesh

Capturing sparks and steel chips.

Stage 2. >

Cartridge Filter

Being coated with TEFLON, featuring 99% of 1 micron filter efficiency.

Stage 3. >

Activated-Carbon Filter

Dispelling peculiar smell before air exhausting.

Revolutionary Characteristics

>

Manual Pulse Cleaning.

>

Easy-access door for maintenance.

>

Cartridge: 99% of 1 Micron filter efficiency.

>

Heavy gauge powder coated steel.

>

Ø6” Blast Gate for external connections.

>

Units equipped with 2 arm options:

PS-300 : Ø6” x 2 holes or Ø8” x 1 hole

PS-500 : Ø8” x 2 holes

Optional Accessories

> HEPA Filter

SPECIFICATIONS

We reserve the right to make changes in SmartVent products in order to improve design or performance characteristics without further notice.

HOW IT WORKS

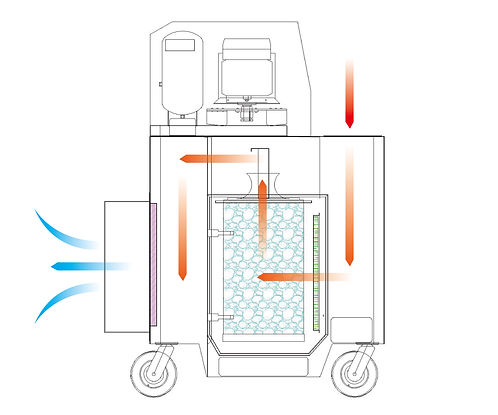

PS-500 Airflow Directions

SPECIFICATIONS

HOW IT WORKS

STEP 1.

Fume extracted via Table Surface Hole Inlet 1, and downward-drafted into the Filtration Chamber.

STEP 2.

Being passed through the Aluminum Mesh 2 for capturing welding sparks.

STEP 3.

And then conducted to Cartridge Filter 3 for dust filtration 3

STEP 4.

Heavier dust falling down to the Dust Drawer 4

STEP 5.

Air gets through the Blower 5 and being exhausted out of Exhaust Outlet 6.

APPLICATIONS

Welding Fumes

Soldering Fumes

Dry Smoke & Powders

Welding Fumes

1/4

APPLICATIONS

No.1, Lane 119, Section 3, Dafeng Rd., Tanzih Dist., Taichung City 427, Taiwan

Tel +886-4-2531-5608

Fax +886-4-2531-5022

bottom of page